Garlic / Onion / Potato Packaging Equipment , Semi Automatic Bagging Machinery

-

Highlight

potato bagging equipment

,potato bagging machine

,Food Industry Bagging Machinery

-

Dimension(LWH/cm)L2500 W2350 H1900

-

ApplicationFood Industry

-

Bag Size(mm)Customized

-

Voltage220V-380V

-

Packaging Speed150~240 Bags/hour

-

Power2.5KW

-

StandardCE

-

Automatic GradeSemi-Automatic

-

Place of OriginChina

-

Brand NameRL

-

CertificationCE

-

Model NumberDCS-SP-NET

-

Minimum Order Quantity1 Set/Sets

-

Pricenegotiation

-

Packaging DetailsStandard Export Wooden Case

-

Delivery Time20 working days after received your payment

-

Payment TermsL/C,T/T

-

Supply Ability20 Set/Sets per Month

Garlic / Onion / Potato Packaging Equipment , Semi Automatic Bagging Machinery

Automatic Potato Bagging Machine , Orange / onion / apple Packaging Machine , 300-400bags / hour

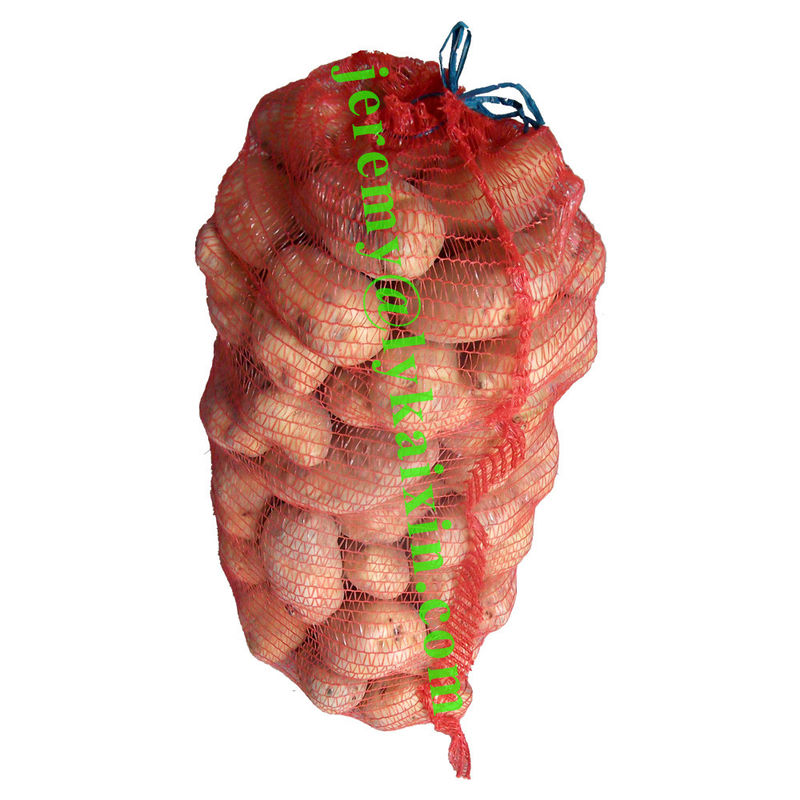

Suitable Material:

potato, onion,garlic,apple etc.

| Technical parameter | |||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

FAQ

1. Can you offer oversea service?

Engineers available to service overseas;

2. How to use the machine?

We will supply the installation catalogue or video online;

3. How about the guarantee period?

One year after machine ex factory

4. What's the payment term?

L/C or TT is accepted.

5. What is the lead time?

25 days after received the deposit.

Our Advantage:

1. Use leading technology of feeding system ,combine inveter to adjust all necessary motor speed.

2. Ensure whole machine life after online sales service .

3. We ourselves file the programme of weighing controller, ensure most easlist operation and setting parameters.

Main Function:

Automatic filling system and dosing weighing balance

Automatic conveyor belt transportation

Automatic sewing or heat sealing machine(based on bag types)

Electric control cabinet and weighing controller

Main operation:

Manual place the bags into clamp bar-->Automatic filling and dosing-->Automatic bag discharge-->Automatic belt conveyor transportation-->Bag sewed or sealed-->Next Round